Xian HeGuangdong Xianhe Technology Group Co., Ltd

-

Hot search:SEMI package cleaning machine

Xian HeGuangdong Xianhe Technology Group Co., Ltd

In the modern automotive industry, connectivity is the cornerstone of innovation. From advanced infotainment systems to critical vehicle diagnostics, reliable connections are essential. D-SUB connectors, with their proven versatility and durability, have emerged as a key component in driving automotive connectivity forward.

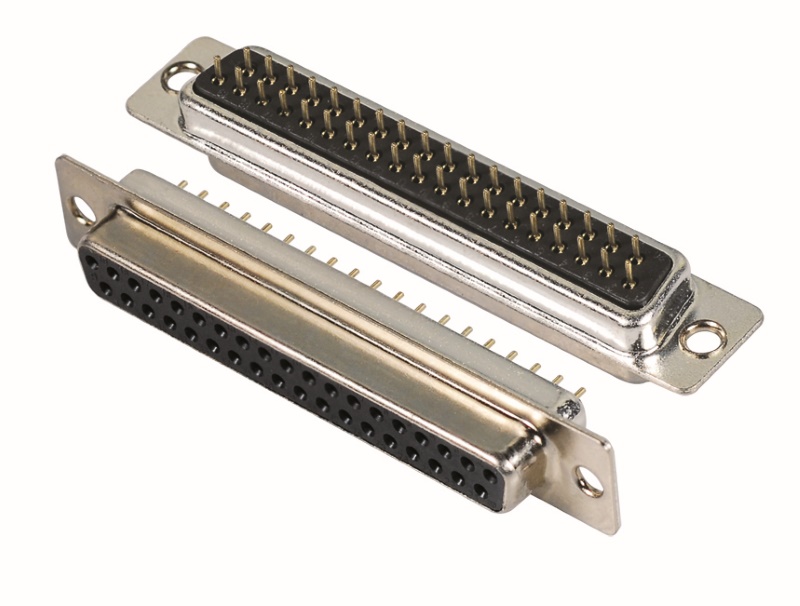

D-SUB connectors, named for their D-shaped shell, are multi-pin connectors widely used across industries for data, power, and signal transfer. Their robust construction and customizable configurations make them a preferred choice for automotive applications.

In automotive environments, where components are subjected to extreme conditions like vibration, temperature fluctuations, and electromagnetic interference, D-SUB connectors provide:

Reliable Performance: Engineered for robust connections that ensure uninterrupted signal transmission.

Versatility: Suitable for various automotive systems, from engine management to infotainment.

Durability: Built to withstand harsh environments, ensuring longevity.

High Pin Density

D-SUB connectors can accommodate a large number of pins in a compact form factor, making them ideal for space-constrained automotive designs.

Secure Locking Mechanisms

Locking screws or clips ensure connectors remain secure even in high-vibration environments, such as engine compartments.

Shielding Against EMI

With metal shells and shielding options, D-SUB connectors protect against electromagnetic interference, crucial for maintaining signal integrity in modern vehicles.

Wide Operating Temperature Range

Designed to function in extreme heat or cold, D-SUB connectors are suitable for diverse automotive climates.

Customizable Configurations

Available in multiple sizes, pin counts, and mounting options, D-SUB connectors can be tailored to specific automotive needs.

Engine Control Units (ECUs)

D-SUB connectors facilitate data and signal transfer between ECUs and other vehicle systems, ensuring seamless engine management.

Infotainment Systems

These connectors provide reliable connections for audio, video, and navigation systems, enhancing the in-car experience.

Diagnostic Interfaces

Automotive diagnostics rely on D-SUB connectors to transmit data between the vehicle and external diagnostic tools.

Battery Management Systems

Electric and hybrid vehicles utilize D-SUB connectors to monitor and manage battery performance.

Safety Systems

From airbags to anti-lock braking systems, D-SUB connectors play a role in transmitting critical signals to ensure passenger safety.

Ease of Maintenance

Their standardized design allows for straightforward assembly and disassembly, reducing downtime during repairs.

Cost-Effectiveness

The reliability and longevity of D-SUB connectors minimize replacement costs over the vehicle's lifecycle.

Compatibility with Legacy Systems

Many automotive manufacturers continue to use D-SUB connectors due to their proven performance and compatibility with existing systems.

Scalability

As automotive technologies advance, D-SUB connectors can adapt to accommodate new functionalities and higher data rates.

Assess Environmental Conditions

Ensure the connector is rated for the temperature, humidity, and vibration levels typical of its intended application.

Consider Pin Requirements

Choose a connector with the appropriate pin count and configuration to meet your system's needs.

Check Compatibility with Other Components

Verify that the connector is compatible with cables, housings, and other system components.

Evaluate EMI Shielding Needs

For systems prone to interference, opt for connectors with enhanced shielding features.

Miniaturization: As vehicles become more compact and feature-rich, smaller D-SUB connectors will be in demand.

Increased Data Speeds: Evolving vehicle technologies require connectors capable of handling higher data transfer rates.

Sustainability: Eco-friendly materials and manufacturing processes are becoming a focus in connector production.

D-SUB connectors have proven their value in the automotive industry by providing reliable, durable, and versatile connectivity solutions. As vehicles continue to integrate more advanced technologies, these connectors remain a cornerstone of innovation, supporting everything from engine management to infotainment systems.

By offering robust performance and adaptability, D-SUB connectors ensure that automotive systems remain connected and efficient, driving the future of mobility forward.

SweepWechat

SweepPersonal wechat